Extended-Release Tablet

Components:

- Active Pharmaceutical Ingredient (API): The drug itself, such as metformin in a diabetes medication.

- Polymers: Substances that control the release rate of the drug, such as hydroxypropyl methylcellulose (HPMC).

- Fillers: Inert substances that help make up the tablet’s bulk, like microcrystalline cellulose.

- Binders: Agents that help hold the tablet together, such as polyvinylpyrrolidone (PVP).

- Disintegrants: Substances that help the tablet break down in the digestive system, such as croscarmellose sodium.

- Lubricants: Materials that prevent the tablet ingredients from sticking to manufacturing equipment, like magnesium stearate.

Formulation Process:

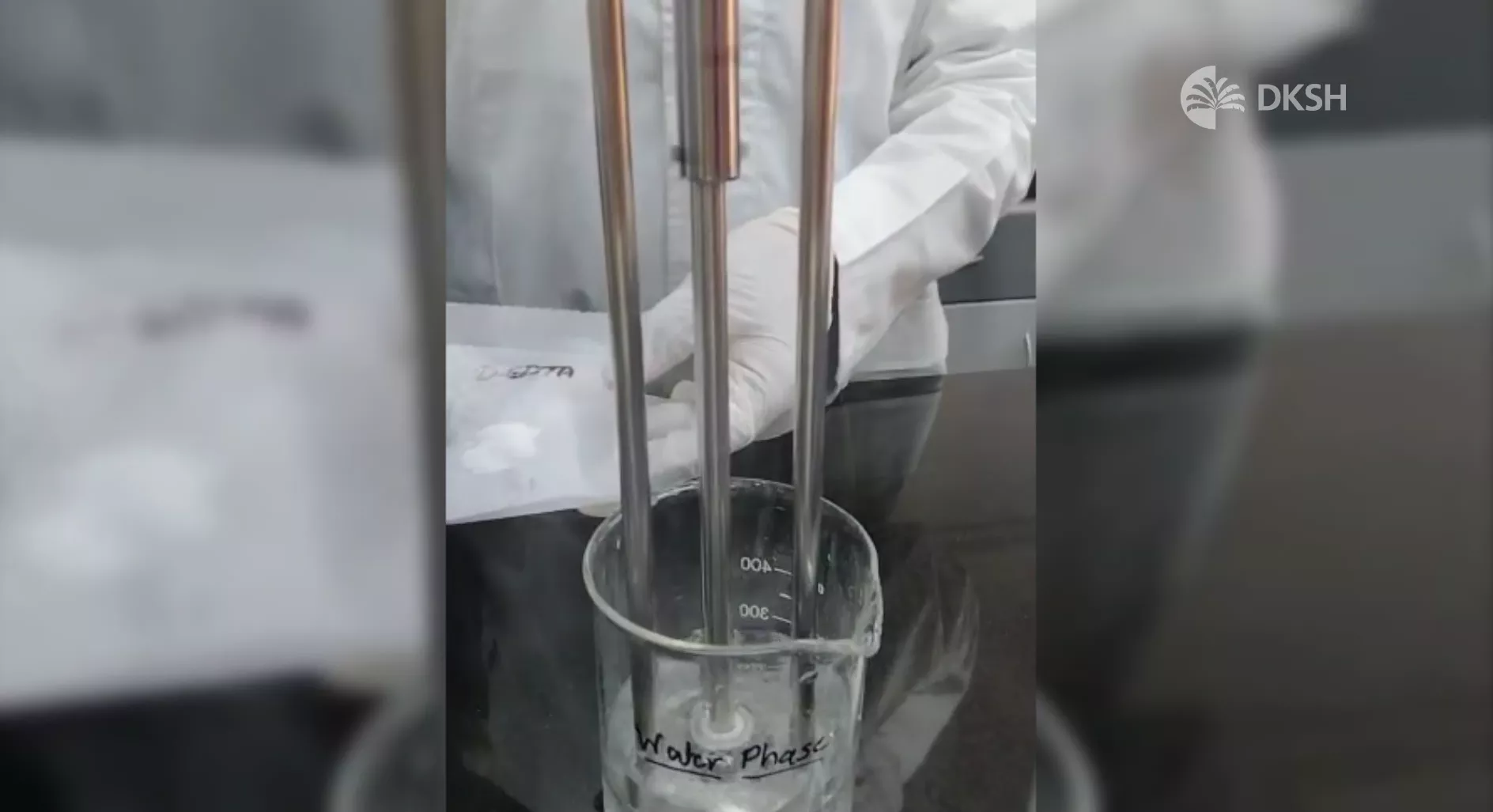

- Blending: The API is mixed with excipients (inactive components) to achieve a uniform distribution.

- Granulation: The blend is granulated to form granules that improve flowability and compressibility.

- Compression: Granules are compressed into tablet form, creating the extended-release matrix.

- Coating: Tablets may be coated to control release, protect the API, or improve appearance.

Benefits:

- Improved Compliance: Patients take fewer doses, leading to better adherence to the medication regimen.

- Stable Drug Levels: Consistent drug levels in the bloodstream reduce peaks and troughs, potentially improving efficacy and reducing side effects.

- Convenience: Extended-release formulations often require only once-daily dosing.

Significance: This formulation example highlights how pharmaceutical science aims to enhance the effectiveness and convenience of medications by designing drug delivery systems that improve patient outcomes and compliance.